Are you staring at spreadsheets, trying to justify the higher per-unit cost of sustainable packaging? The numbers for traditional plastic seem safer, but you know the market is shifting. You feel stuck between your company’s budget and its sustainability goals, worried that making the wrong choice could hurt your bottom line.

Yes, it is a smart financial move. While eco-friendly materials like bagasse or PLA can have a higher upfront cost, a full cost-benefit analysis reveals long-term savings. These come from reduced waste disposal fees, increased customer loyalty, and avoidance of potential regulatory fines. Sustainable packaging is not just an expense; it’s an investment in brand reputation, market resilience, and operational efficiency that pays off significantly over time.

This sounds good on paper, but I know you’re like me—you need to see the breakdown. For years, I’ve helped packaging specialists like you build the business case for this transition. It’s about looking past the initial invoice and seeing the complete picture. Making a solid argument for this change is crucial, and it starts by understanding every piece of the puzzle. So, let’s dig into the real numbers and the less obvious benefits to see how it truly pays off.

What are the direct costs of switching to eco-friendly packaging?

The first number you see is the price per case, and it’s often higher for sustainable options. This initial sticker shock can stop a great initiative in its tracks. You’re pressured to keep procurement costs low, and justifying this increase to management seems like an uphill battle. The fear is that this one change will cascade into an unmanageable expense.

The direct costs involve more than just the material price. You must factor in sourcing, new supplier validation, potential equipment adjustments for different materials, and staff training. For materials like PLA or bagasse, the cost per unit might be 15-30% higher than polystyrene. However, a good sourcing partner can help you find economies of scale and optimize logistics, which can significantly narrow this gap and make the initial investment much more predictable.

Let’s break down these initial expenses because they are the first hurdle you need to clear with your finance team. I always advise clients to look at it as a "Total Cost of Transition" rather than just a "Unit Price Increase." This gives a more honest and comprehensive view.

First is the material cost. Yes, a bagasse container often costs more than a styrofoam one. This is due to raw material sourcing and manufacturing processes. But this is also where a strategic partner like Ecosourcecn comes in. We can help you forecast demand and place larger, consolidated orders to achieve better volume pricing.

Second, you have sourcing and certification costs. Finding a reliable supplier who can prove their products are certified (e.g., BPI, EN13432) takes time and resources. I remember working with a client who wasted months on a supplier whose certifications weren’t valid in their country. Vetting partners properly upfront saves a lot of money and headaches later.

| Finally, consider these operational adjustments: | Direct Cost Category | Description | Potential Mitigation Strategy |

|---|---|---|---|

| Machinery & Equipment | Some packaging lines might need adjustments for different materials. For example, sealing PLA lids may require different temperature settings than PET. | Consult with your supplier. Many modern eco-materials are designed as "drop-in" replacements and require minimal changes. | |

| Logistics & Warehousing | Sustainable materials can sometimes be bulkier, affecting shipping and storage space. | Optimize your supply chain. Order more frequently or work with a supplier who can manage regional warehousing to reduce your footprint. | |

| Staff Training | Your team needs to understand how to handle, store, and communicate the benefits of the new packaging to customers. | Develop simple training materials. Your supplier can often provide information on material benefits and disposal instructions. |

These are real, tangible costs. But by planning for them, you can build a realistic budget that won’t surprise your stakeholders down the line.

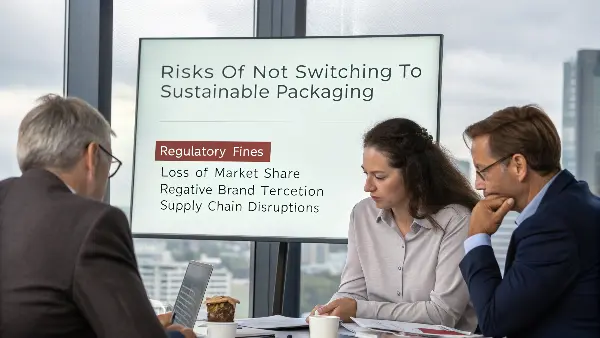

What are the risks of NOT switching to sustainable packaging?

You might think that sticking with the status quo is the safest, most cost-effective option. It’s the "devil you know," and the supply chain is already established. But in today’s world, inaction carries its own massive, often hidden, price tag. Delaying the switch isn’t just maintaining your current budget; it’s exposing your business to growing financial and reputational risks.

The risks of not switching are significant and can outweigh the initial cost of transitioning. You face increasing regulatory fines from plastic bans, loss of market share as consumers flock to greener competitors, and negative brand perception that is difficult to repair. Supply chain disruptions for petroleum-based plastics are also becoming more common. Sticking with traditional plastic is no longer a safe bet; it’s a gamble against market trends, consumer sentiment, and government policy.

I’ve seen companies get hit hard by these risks, and it’s a tough lesson to learn reactively. Let’s look at the three biggest costs of inaction that I’ve seen impact businesses firsthand.

First, regulatory penalties. Governments worldwide are cracking down on single-use plastics. Canada, the EU, and many individual states have bans or taxes in place. I worked with a food service chain that had to scramble when their city announced a sudden ban on polystyrene. The cost of quickly sourcing a compliant alternative under pressure was far higher than if they had planned a gradual transition a year earlier. These fines and last-minute changes destroy budgets.

Second is brand erosion. Your customers are paying attention. A Nielsen study found that 66% of consumers are willing to pay more for sustainable brands. When your competitor puts a "100% Compostable" label on their cup and you don’t, you start losing customers. This isn’t just about a few eco-warriors; it’s becoming a mainstream expectation. Losing brand loyalty is an invisible cost that slowly drains your revenue.

Third, you have talent acquisition and retention. This is one people often forget. The best employees want to work for companies that align with their values. We had a client, a large cafe chain, who told us their new sustainability initiatives were a major talking point in job interviews. It helped them attract passionate and motivated staff. In a competitive labor market, being a company people are proud to work for is a huge financial advantage. Failure to adapt makes you a less attractive employer, increasing recruitment costs and turnover. Sticking with plastic is no longer just a packaging choice; it’s a statement about your company’s vision for the future.

How can sustainable packaging reduce long-term operational costs?

After you’ve accounted for the initial investment, the real financial story begins to unfold. The "benefit" side of the cost-benefit analysis is where sustainable packaging truly shines. Many businesses focus only on the per-unit cost and miss the bigger picture. I’ve found that the biggest savings are often indirect and appear over time, but they have a massive impact on the bottom line.

Sustainable packaging can significantly reduce long-term costs by lowering waste management fees, as compostable materials divert waste from expensive landfills. It can also open doors to tax incentives and green business grants. Furthermore, efficient, lightweight designs can lower shipping costs. By building a circular economy model, you turn a disposable item into a resource, creating operational efficiencies that petroleum-based plastics simply cannot offer.

When I walk a client through a long-term financial model, we focus on three areas where the savings really add up.

The first and most direct is reduced waste disposal fees. Many municipalities charge businesses based on the volume and weight of non-recyclable trash they send to the landfill. If your business switches to certified compostable packaging, you can often work with commercial composting services. These services can be cheaper than traditional waste hauling. I have a partner in the restaurant industry who cut their monthly waste management bill by over 20% simply by diverting all of their food scraps and compostable packaging away from the landfill. That’s a recurring saving that goes straight to their profit margin.

Second, you have supply chain stability. The price of petroleum, the raw material for most plastics, is notoriously volatile. Geopolitical events can cause sudden price spikes that wreck your budget. In contrast, the feedstocks for materials like PLA (cornstarch) and bagasse (sugarcane fiber) tend to have more stable pricing. By diversifying your packaging portfolio with plant-based materials, you insulate your business from the volatility of the oil market, leading to more predictable and stable procurement costs over the years.

| Finally, think about operational efficiency. | Savings Area | How It Works | Real-World Example |

|---|---|---|---|

| Material Reduction | Clever design with sustainable materials can reduce the total amount of packaging needed. | Switching from a bulky plastic clamshell to a sleeker, form-fitting bagasse container can reduce material use by weight. | |

| Tax Credits & Grants | Governments often offer financial incentives for businesses that adopt sustainable practices. | A business might qualify for a green grant to cover a portion of the initial transition costs. | |

| Corporate Partnerships | Large corporations with sustainability mandates prefer to partner with suppliers who share their values. | Becoming a sustainable business can make you a more attractive partner for large, lucrative contracts. |

These long-term benefits are not just theoretical. They are tangible financial returns that make the initial investment in sustainable packaging a very smart business decision.

Does eco-friendly packaging actually attract more customers?

Ultimately, every business decision comes down to growth. You can cut costs and manage risks, but you also need to increase revenue. The question of whether customers will actually choose you because of your packaging is a critical one. You see the trends, but you worry if it translates to actual sales in your specific market.

Absolutely. Eco-friendly packaging acts as a powerful marketing tool that directly influences purchasing decisions, attracting a growing segment of conscious consumers. Studies show that products with sustainable packaging are perceived as higher quality and more trustworthy. This builds powerful brand loyalty, increases repeat business, and provides a clear competitive advantage. It’s not just packaging; it’s a visible commitment to shared values that customers are willing to pay for.

I can tell you from experience, packaging is often the first—and sometimes only—physical interaction a customer has with your brand. It’s your silent salesman. When I work with brands on private label customization, we don’t just talk about logos; we talk about storytelling. Your packaging tells a story.

A story of sustainability resonates deeply today. Think about the "Instagrammable" moment. Customers love to share photos of products that make them feel good about their choices. A beautifully designed bagasse bowl or a cup with a clear "Compostable" message is far more likely to be shared on social media than a generic styrofoam container. I’ve seen small cafes gain huge local followings because their eco-friendly takeaway cups became a status symbol. That’s free marketing that generates real foot traffic.

Moreover, it builds brand loyalty that goes beyond the product itself. When a customer knows you’ve invested in packaging that’s better for the planet, it creates an emotional connection. They see you as a brand that cares. This emotional equity is incredibly valuable. It means that even if a competitor offers a slightly lower price, your customers will stick with you because they believe in what your brand stands for. This reduces customer churn and increases the lifetime value of each customer—a metric every CFO loves.

Finally, it opens up new market segments. Consider corporate catering or supplying to large, eco-conscious events. These B2B clients often have strict sustainability requirements in their procurement policies. By having certified sustainable packaging, you are automatically eligible for these lucrative contracts. We helped a small food producer get their products into a major tech company’s headquarters precisely because their packaging met the company’s zero-waste policy. Their plastic-using competitors couldn’t even bid. It’s a clear differentiator that unlocks new revenue streams.

How do you measure a successful transition to sustainable packaging?

So, you’ve decided to make the switch. The business case is strong. But how do you prove it was the right decision six or twelve months down the line? You need clear, data-driven ways to measure success. Without Key Performance Indicators (KPIs), you’re just hoping for the best. A well-defined measurement strategy is essential to demonstrate real ROI to your leadership team.

A successful transition is measured by a blend of quantitative and qualitative metrics. Quantitatively, track the Cost per Unit, changes in waste management fees, and sales lift in products with new packaging. Qualitatively, monitor customer feedback through surveys and social media sentiment, as well as employee engagement. A truly successful switch shows a positive financial return, improved brand perception, and a stronger market position within a defined timeframe.

To prove the value of the transition, you need a balanced scorecard. I always recommend my clients set up a simple dashboard to track progress against the goals we set at the start. It doesn’t need to be complicated, but it does need to be consistent.

First, let’s look at the financial metrics. These are the hard numbers that everyone in the C-suite will want to see.

- Total Cost of Ownership (TCO): Don’t just track the initial unit cost. Calculate the TCO, which includes the unit price, shipping, new equipment (amortized), and waste disposal fees. Compare this to the TCO of your old plastic packaging. Your goal is to see the TCO for sustainable options trend downward and eventually become lower than plastic.

- Sales Data: Tag products that use the new packaging in your sales system. Run A/B tests if possible, offering the same product in old and new packaging in different locations. Measure if there is a sales lift or an increase in the average transaction value for the eco-friendly options.

- Cost Avoidance: Track the money you didn’t have to spend. This includes avoided plastic taxes, regulatory fines, or the cost of a PR crisis related to environmental issues.

| Next, focus on the customer and brand metrics. | Metric | How to Measure | Success Indicator |

|---|---|---|---|

| Customer Feedback | Run simple one-question surveys on receipts ("Did our eco-friendly packaging influence your purchase?"). Monitor online reviews for keywords like "packaging," "sustainable," "compostable." | An increase in positive mentions and a high "yes" rate on surveys. | |

| Social Media Engagement | Track mentions of your brand alongside sustainability keywords. Measure likes, shares, and comments on posts about your new packaging. | Higher engagement rates and user-generated content featuring your packaging. | |

| Brand Perception | Conduct yearly brand health surveys to see if your brand is more strongly associated with terms like "innovative," "responsible," and "high-quality." | A measurable shift in brand perception towards positive, eco-conscious attributes. |

By tracking these KPIs, you move the conversation from "this is the right thing to do" to "this is a profitable and strategic business decision." The data will tell a compelling story, proving the transition was a clear success.

Conclusion

Making the switch from plastic to sustainable packaging isn’t just about environmental responsibility; it’s a calculated business strategy. A thorough cost-benefit analysis reveals that the long-term gains in operational savings, brand loyalty, and market resilience far outweigh the initial material costs. This transition is a smart, forward-thinking investment in the financial health and future of your brand.