Your business is under pressure to move away from traditional plastics, but navigating the world of "eco-friendly" alternatives is a minefield. You need a sustainable solution that’s genuinely better for the planet, not just a label. Making the wrong choice can damage your brand’s reputation and lead to unintended environmental consequences. Let’s dive into the facts.

Yes, PLA (Polylactic Acid) generally has a lower environmental impact than conventional plastics like PET or PS. This is because PLA is derived from renewable plant resources, its production typically generates fewer greenhouse gas emissions, and it is commercially compostable, allowing it to break down into natural components under the right conditions. However, its green credentials depend heavily on proper end-of-life disposal in industrial composting facilities.

The simple answer is a good starting point, but as a packaging specialist, you know the details matter. The true environmental impact isn’t just about the final product; it’s about the entire life cycle, from creation to disposal. To make an informed decision for your business, you need to understand the full story. Let’s break down the key differences stage by stage to see where PLA truly shines and where challenges remain.

What Are the Core Material Differences Between PLA and Traditional Plastics?

You’re likely familiar with the term "fossil fuels," but explaining the alternative can be tricky. When customers see "plant-based," they want to know what it really means for sustainability. Without a clear understanding of the raw materials, it’s hard to confidently stand behind your packaging choices and communicate their value. Let’s clarify the fundamental difference in their origins.

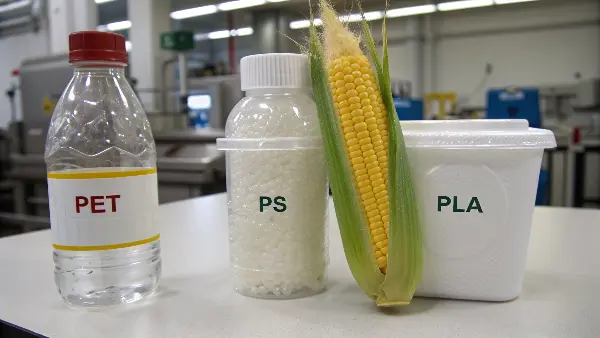

Traditional plastics, like Polyethylene Terephthalate (PET) and Polystyrene (PS), are petrochemicals derived from non-renewable fossil fuels such as oil and natural gas. In contrast, PLA is a bioplastic made from fermenting renewable plant starches from sources like corn, sugarcane, or cassava. This foundational difference means PLA starts its life cycle with a much smaller carbon footprint, as it relies on agriculture rather than fossil fuel extraction.

To truly appreciate the impact of this difference, we need to look closer at what it means to source from plants versus petroleum. This isn’t just about renewability; it’s about the entire supply chain and the associated environmental baggage each material carries from day one. I’ve worked with many clients like Jacky, a packaging specialist in Canada, who need to justify their material choices not just on performance, but on verifiable sustainability metrics. The origin story of your material is the first and most critical chapter.

Sourcing: Plants vs. Petroleum

The primary distinction lies in the feedstock. Traditional plastics are a byproduct of the oil and gas industry, a sector notorious for its environmental impact, from drilling and extraction to refining. This process releases significant amounts of carbon dioxide and other pollutants, and it relies on a resource that we cannot replenish.

PLA, on the other hand, is born from agriculture. The process starts by harvesting crops rich in starch. This starch is then converted into sugar, which is fermented to produce lactic acid. Finally, the lactic acid is polymerized to create Polylactic Acid. Because plants absorb CO2 as they grow, the carbon footprint of the raw material is inherently lower.

Here’s a simplified breakdown:

| Feature | Polylactic Acid (PLA) | Traditional Plastics (PET, PS, etc.) |

|---|---|---|

| Primary Source | Renewable plant starch (corn, sugarcane) | Non-renewable fossil fuels (crude oil, natural gas) |

| Resource Type | Renewable (can be regrown annually) | Finite (will eventually run out) |

| Initial Carbon Impact | Lower; plants absorb CO2 during growth | Higher; extraction and refining are carbon-intensive |

| Supply Chain Concerns | Land use for crops, agriculture practices | Oil spills, habitat destruction, geopolitical instability |

This initial advantage is a key reason why many eco-conscious brands are making the switch. However, it’s also important to consider the agricultural impact, such as land and water use. At Ecosourcecn, we advocate for sourcing PLA from responsibly managed, non-GMO crops to mitigate these concerns and ensure the sustainability is holistic.

How Do Their Production Processes Compare Environmentally?

You’ve made the decision to source a "greener" material, but you know that manufacturing can have its own hidden environmental costs. It’s frustrating when a product made from a sustainable source uses an energy-intensive process that negates the benefits. You need to be sure that the entire production journey, not just the raw material, aligns with your company’s sustainability goals.

The production of PLA is significantly more energy-efficient and releases fewer greenhouse gases compared to the manufacturing of traditional petroleum-based plastics. Studies conducting a life-cycle analysis have shown that producing PLA requires less non-renewable energy and results in a substantial reduction in CO2 emissions. For instance, creating PLA from corn can use up to 65% less energy than producing its conventional plastic counterparts.

This is a critical point that often gets overlooked. The benefits of PLA aren’t just theoretical; they are measurable. I remember working on a project for a large beverage company that was considering a switch from PET bottles to PLA. Their primary concern was whether the switch would genuinely reduce their carbon footprint. We presented them with life-cycle assessment (LCA) data that clearly demonstrated the advantages.

Energy Consumption and Emissions

The magic of PLA manufacturing lies in its lower processing temperatures and more efficient chemical processes. The polymerization of lactic acid into PLA simply requires less heat and energy than breaking down and reforming long hydrocarbon chains from crude oil.

My insights from industry reports confirm this. A comparative study on PET and PLA drinking water bottles revealed some compelling numbers. The research concluded that producing PLA bottles not only reduces CO2 emissions but also lowers overall toxicity and significantly cuts down the demand for non-renewable energy.

Let’s look at the key environmental metrics in the production phase:

| Environmental Metric | PLA Production | Traditional Plastic Production | Impact Difference |

|---|---|---|---|

| Energy Input | Lower (less energy needed for polymerization) | Higher (energy-intensive refining and cracking) | PLA can use 20-50% less energy. |

| Greenhouse Gas Emissions | Lower (fewer fossil fuels burned) | Higher (major source of industrial CO2) | PLA can generate up to 75% fewer GHG emissions. |

| Water Usage | Primarily agricultural; varies by crop and region | High in refining and cooling processes | Can be comparable, but PLA’s source is renewable. |

These figures are powerful. When you, as a buyer, choose a PLA product, you’re not just choosing a plant-based material; you’re choosing a less polluting manufacturing process. This has a direct and positive impact on global warming potential and helps your company meet its emission reduction targets. It transforms your packaging from a simple container into a statement about your commitment to a cleaner industrial future.

What Happens to PLA and Plastic After Use?

Your product has been used, and the packaging is now empty. This is where the environmental story truly diverges. With traditional plastics, you know the bleak reality: landfills overflowing and oceans polluted. But what about PLA? You’ve heard it’s "compostable," but you’re worried about what that actually means and if it will just create a different kind of waste problem.

At the end of its life, PLA is designed to be commercially composted, where it biodegrades into water, carbon dioxide, and organic biomass within months. In contrast, traditional plastics persist in the environment for hundreds of years, breaking down into harmful microplastics. However, for PLA to be beneficial, it must be sent to an industrial composting facility with the right conditions; it will not biodegrade in a backyard compost or a landfill.

This end-of-life stage is the most critical and often the most misunderstood aspect of PLA. For someone like Jacky, ensuring proper disposal is as important as the material choice itself. It requires clear communication with consumers and access to the right infrastructure. Without the correct disposal pathway, the environmental benefits of PLA can be lost. It’s our responsibility as businesses to be part of the solution by educating our customers and advocating for better waste management systems.

The Pathways of Disposal: Composting vs. Landfill

Let’s break down what happens in each scenario.

-

Industrial Composting (The Ideal Path for PLA): In a commercial facility, temperatures are consistently high (55-70°C), and humidity and microbes are carefully controlled. Under these conditions, PLA products break down completely in about 90-180 days. The resulting compost can be used to enrich soil, creating a closed-loop system. This is the circular economy in action.

-

Landfill (The Worst Path for Both):

- Traditional Plastic: It sits there for centuries, leaching chemicals and taking up space.

- PLA: In an anaerobic (oxygen-free) landfill environment, PLA degrades extremely slowly, just like traditional plastic. If it does break down, it can release methane, a potent greenhouse gas. This is why diverting PLA from landfills is essential.

-

Recycling (A Complex Issue):

- Traditional Plastic: Mature recycling streams exist for plastics like PET (#1) and HDPE (#2), though recycling rates are often disappointingly low.

- PLA: PLA has its own recycling code (#7) and can be recycled, but it requires a separate stream. If mixed with PET, it can contaminate the batch, rendering it unusable. The infrastructure for PLA recycling is still developing and not yet widely available.

Here’s a table to visualize the end-of-life options:

| Disposal Method | PLA Outcome | Traditional Plastic Outcome | Environmental Winner |

|---|---|---|---|

| Industrial Composting | Biodegrades into soil nutrients. | Does not break down. | PLA (by a huge margin) |

| Landfill | Decomposes very slowly; may release methane. | Stays intact for 500+ years, breaks into microplastics. | Neither (both are poor options) |

| Recycling | Recyclable in specific streams, but contaminates PET. | Recyclable in established streams. | Traditional Plastic (currently, due to infrastructure) |

| Litter/Ocean | Breaks down faster than PET but still a pollutant. | Persists for centuries, harming marine life. | PLA (less persistent, but still harmful) |

Choosing PLA is a commitment to advocating for and utilizing the proper disposal infrastructure. It’s about designing for a better "afterlife" for our products.

Conclusion

Ultimately, the evidence clearly shows that PLA holds a significant environmental advantage over traditional plastics when its entire life cycle is considered. From its renewable, plant-based origins to a less energy-intensive manufacturing process, PLA starts and lives its life with a smaller carbon footprint. Its ability to be commercially composted provides a sustainable end-of-life solution that conventional plastics simply cannot offer.