Trying to import bamboo tableware but hitting regulatory roadblocks? It’s frustrating when shipments are delayed or rejected because of complex rules about food safety. You need a clear path to ensure your products are compliant, safe, and accepted by customs without any issues, protecting your brand’s reputation and your bottom line.

To navigate bamboo import regulations, first, understand the specific rules for your target market, like the EU’s restrictions on bamboo-plastic composites and North America’s FDA requirements. Focus on testing for harmful substances like formaldehyde and melamine. Ensure your supplier provides valid lab reports and a Declaration of Compliance (DoC). Proper documentation is key to avoiding customs delays and ensuring your products are safe for consumers. This proactive approach ensures a smooth import process.

I talk to business owners and packaging specialists like you every day. Many are excited about switching to sustainable materials like bamboo. But that excitement can quickly turn into anxiety when they face the wall of import regulations. It’s a complex world, and a single misstep can be costly. But it doesn’t have to be that way. Once you understand the core principles and know what to look for, you can import with confidence. Let’s break it down together, step by step, so you can make your next shipment a success.

What Are the Core Regulations for Bamboo FCMs in the EU and North America?

Are you confused by the different rules for bamboo products in Europe versus North America? It’s a major headache trying to keep track of what’s allowed where, especially with regulations constantly changing. You need to know the exact requirements for each market to avoid costly mistakes and ensure your products are legal and safe for your customers.

In the EU, bamboo mixed with plastics (like melamine) is heavily restricted for food contact materials (FCMs) under Regulation (EU) No 10/2011, as it’s considered an unauthorized plastic additive. For North America, the FDA regulates bamboo FCMs under 21 CFR, focusing on ensuring the material is sanitary and free of poisonous substances. Canada has similar safety requirements under its Food and Drugs Act. Always verify the specific rules for your destination country.

When I first started in this business, the biggest learning curve was realizing that "eco-friendly" doesn’t automatically mean "market-ready." A product that’s perfectly fine for one country could be illegal in another. This is especially true for bamboo food contact materials (FCMs). The rules are different, and you need to know them.

Understanding the EU’s Stance

The European Union has taken a very strict position, particularly on bamboo-plastic composites. These are products made from bamboo powder mixed with a polymer, often melamine resin, to bind it all together. For years, these were sold as natural bamboo products. However, the EU clarified that bamboo powder is an unauthorized plant-based additive in plastic FCMs. This means importing these composite products into the EU is now largely prohibited. The focus is on ensuring that only authorized substances are used in plastic materials that touch food. For products made of 100% bamboo (like a cut and carved bamboo bowl), the general safety requirements of Regulation (EC) 1935/2004 apply, which is much more straightforward.

Navigating North American Rules

In the United States and Canada, the approach is different. The U.S. Food and Drug Administration (FDA) doesn’t have a specific ban on bamboo-plastic composites. Instead, any FCM is regulated under Title 21 of the Code of Federal Regulations (CFR). The core principle is that the material must be "generally recognized as safe" (GRAS) for its intended use. It must not transfer any harmful substances to the food it touches. This puts the responsibility on the manufacturer and importer to prove safety through testing. Similarly, Health Canada and the Canadian Food Inspection Agency (CFIA) require that all food packaging is safe and doesn’t pose a risk to the consumer.

Here is a simple comparison:

| Region | Key Regulation / Principle | Main Hurdle for Bamboo Composites |

|---|---|---|

| European Union (EU) | Regulation (EU) No 10/2011 on plastic FCMs | Bamboo powder is an unauthorized filler in plastic. |

| United States (USA) | FDA 21 CFR | Must prove the final material is safe and doesn’t leach harmful chemicals. |

| Canada | Food and Drugs Act | General safety requirement; must not impart harmful substances to food. |

Understanding this key difference is the first step to a successful import strategy.

Why Are Formaldehyde and Melamine Such a Big Deal for Bamboo Products?

Have you heard about the health risks associated with formaldehyde and melamine in bamboo tableware? It’s alarming to think that the eco-friendly products you source could potentially harm customers. You need to understand why these chemicals are a problem and how to ensure your products are completely free from them, or at least within safe limits.

Formaldehyde and melamine are often used as binding resins in composite bamboo products (bamboo powder mixed with plastic). The health risk arises when these chemicals ‘migrate’ from the tableware into food, especially hot or acidic foods. High levels of migration are toxic and can cause health issues. Regulators have set strict Specific Migration Limits (SMLs) to protect consumers, making testing for these substances a non-negotiable step for any importer.

The issue isn’t with bamboo itself. Natural bamboo is perfectly safe. The problem arises during the manufacturing of composite tableware, where bamboo fiber or powder needs a glue to hold its shape. This glue is often a melamine-formaldehyde resin. While stable at room temperature, this resin can break down under certain conditions.

What is Chemical Migration?

Think of "migration" as chemicals leaching out of the product. When you put hot soup or acidic tomato sauce into a poorly made bamboo-composite bowl, tiny, invisible amounts of formaldehyde and melamine can transfer from the bowl into your food. This is what regulators are trying to prevent. The amount of migration depends on the quality of the resin, the food’s temperature, its acidity, and how long it stays in contact with the material. This is why testing is done using food simulants (like acetic acid to mimic vinegar) at high temperatures to replicate worst-case scenarios.

Health Risks and Regulatory Limits

Both formaldehyde and melamine are substances you don’t want in your food. Long-term exposure to high levels can lead to serious health problems. Because of this risk, regulators worldwide have established strict limits on how much can migrate into food. These are called Specific Migration Limits (SMLs).

For example, in the European Union, the limits are very clear:

- Formaldehyde: The SML is 15 milligrams per kilogram of food (mg/kg).

- Melamine: The SML is 2.5 milligrams per kilogram of food (mg/kg).

I remember a client who came to us after their shipment of bamboo coffee cups was rejected. Their previous supplier gave them a report, but it was for the wrong tests. They had no idea about specific migration limits. They learned the hard way that exceeding these limits means your product is illegal and unsafe. It’s absolutely critical that your supplier can provide lab reports proving their products are well below these official thresholds.

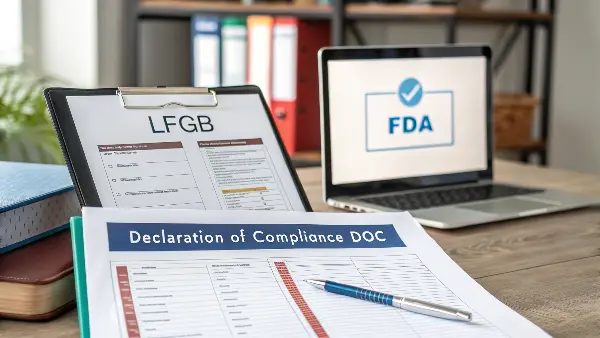

Which Certifications and Lab Tests Prove Your Bamboo Products are Compliant?

Do you feel lost in a sea of acronyms like LFGB, FDA, and DoC? It’s tough to know which tests and certifications are genuinely required and which are just optional extras. You need a clear checklist of the essential tests to request from your supplier so you can prove your products are safe, legal, and ready for your market.

To prove compliance, you need specific lab test reports. For the EU, request migration tests for formaldehyde and melamine according to Regulation (EU) No 10/2011, often under the German LFGB standard. For the US, testing should confirm compliance with FDA 21 CFR 177. You will also need a comprehensive Declaration of Compliance (DoC) from your manufacturer. These documents are your proof that the materials are safe for food contact under intended use conditions.

When you partner with a supplier, you are placing your trust in them. But trust in this industry must be backed by proof. That proof comes in the form of official documents and test reports from accredited, third-party laboratories. Vague promises of "our products are safe" are not enough. You need the paperwork to back it up.

Key Tests for Food Contact Safety

When you’re sourcing bamboo FCMs, especially composites, here are the tests you should be asking for. A good supplier will have these ready.

- Overall Migration Limit (OML) Test: This test measures the total amount of all substances that can migrate from the product into food. It ensures the product is stable and doesn’t transfer unknown chemicals.

- Specific Migration Limit (SML) Test: This is the most critical one for bamboo composites. It specifically measures the migration of known high-risk substances like formaldehyde and melamine. It also checks for heavy metals like lead and cadmium.

- Sensory Testing: This is a simple but important test. It confirms that the product does not transfer any taste or odor to the food.

For products targeting the EU market, these tests are often performed according to the German Food and Feed Act (LFGB), which is considered one of the strictest standards in Europe. If a product passes LFGB testing, it is generally considered safe across the EU.

The Importance of the Declaration of Compliance (DoC)

Besides lab reports, the Declaration of Compliance is arguably the most important document you need. This is a formal, legal statement from the manufacturer that the product complies with all relevant regulations for food contact. It’s not just a simple certificate; it must contain specific information, including:

- Identity and address of the manufacturer.

- Identification of the materials or articles.

- The date of the declaration.

- Confirmation that the products meet the relevant regulations (e.g., Regulation (EC) 1935/2004).

- Information on the substances used, especially those with restrictions.

- Specifications on the intended use (e.g., types of food, temperature limits).

Without a valid DoC, your shipment can be stopped at customs. It’s your primary piece of evidence that you have done your due diligence.

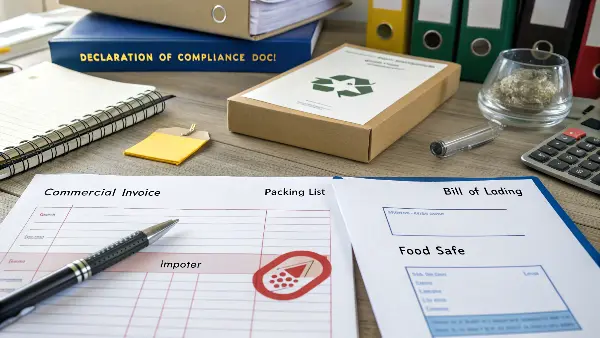

What Documentation and Labeling Are Crucial for a Smooth Customs Clearance?

Are you worried about your sustainable products getting stuck in customs for weeks? It’s a nightmare when a simple paperwork mistake grinds your entire supply chain to a halt. You need to prepare every document and label perfectly to ensure your shipment sails through customs without any delays or special inspections.

For smooth customs clearance, your shipment needs a complete documentation package. This includes the commercial invoice, packing list, bill of lading, and, most importantly, the Declaration of Compliance (DoC) and supporting lab test reports for the food contact materials. Your product labeling must also be compliant, often requiring the "food safe" symbol (fork and glass) in the EU, country of origin, and importer details.

I’ve seen perfect products held up for weeks just because of a missing document. Customs agents don’t have time to guess; if the paperwork isn’t in order, they will put your shipment aside. Creating a documentation checklist is one of the most valuable habits you can develop as an importer. It saves time, money, and a lot of stress.

Assembling Your Customs Documentation Checklist

Before your shipment leaves the factory, ensure your supplier has provided a complete set of digital copies for you to review. The original documents will travel with the freight. Here’s what you need:

- Commercial Invoice: Details the transaction between you and the supplier, including the price, currency, and terms of sale.

- Packing List: Specifies the contents of each box, including quantities, weights, and dimensions. This helps customs verify the shipment’s contents quickly.

- Bill of Lading (B/L) or Air Waybill (AWB): The contract between the shipper and the carrier. It acts as a receipt and a title to the goods.

- Certificate of Origin: States where the goods were manufactured. This is important for determining import duties.

- Food Contact Material Compliance Documents: This is the critical part.

- Declaration of Compliance (DoC): Your primary legal proof.

- Third-Party Lab Test Reports: The evidence that backs up the DoC.

Getting Product Labeling Right

What’s on the product is just as important as the paperwork with the product. Labeling requirements vary, but some common elements are mandatory.

- Food Safe Symbol: In the EU, products intended for food contact must be labeled with the international "glass and fork" symbol unless it’s obvious they are for food use. It’s best practice to include it.

- Traceability Information: A batch or lot number on the product or packaging is essential. This allows you to trace a product back to a specific production run in case of a recall.

- Importer/Manufacturer Information: You often need to include the name and address of the manufacturer or the importer responsible for placing the product on the market.

- Country of Origin: Clearly state "Made in [Country]."

- Instructions for Use: If there are limitations, they must be stated clearly (e.g., "Not for microwave use," "Dishwasher safe up to 70°C").

Getting these details right from the start makes you look professional and helps your shipment move through the system without a hitch.

How Can You Be Sure Your Supplier Truly Understands These Complex Regulations?

Have you ever been let down by a supplier who promised compliance but couldn’t deliver the proof? It’s a huge risk to your business when a partner doesn’t truly grasp the complex web of global regulations. You need a reliable way to vet suppliers and ensure they are experts who can protect your brand, not just salespeople.

To verify a supplier’s expertise, ask direct and specific questions. Don’t just ask "Are you compliant?" Instead, ask for specific test reports for formaldehyde migration under EU Regulation 10/2011. Request a sample Declaration of Compliance to review. Inquire about their experience with EU vs. FDA requirements. A truly knowledgeable supplier like Ecosourcecn will provide detailed, confident answers and complete documentation without hesitation, demonstrating their capability and transparency.

Finding the right supplier is the most important decision you’ll make. A great partner acts as an extension of your team. They don’t just sell you a product; they provide the expertise and documentation you need to succeed. On the other hand, a poor supplier can become your biggest liability. The key is to ask the right questions and look for the right signals during the vetting process.

Key Questions to Ask Potential Suppliers

Go beyond surface-level questions. Dig deeper to test their knowledge.

- "Can you please send me a full, unedited LFGB or FDA test report for this exact product from an accredited lab like SGS, TUV, or Intertek?"

- "Could you provide a sample Declaration of Compliance that you would issue for this order so my compliance team can review it?"

- "How does your manufacturing process for products going to the EU differ from those going to the US, given the EU’s position on bamboo-plastic composites?"

- "What is your traceability system? If there was an issue with one batch, how could you trace it back to the raw materials used?"

- "Can you explain the migration limits for formaldehyde and melamine that you test for?"

A confident, experienced supplier will welcome these questions. They’ll have the answers and documents ready because they do this every day.

Red Flags to Watch Out For

Equally important is knowing what to avoid. Here are some warning signs I’ve learned to spot:

- Vague Answers: If they say "Don’t worry, it’s all compliant" but can’t provide specifics, be cautious.

- Reluctance to Share Documents: A supplier who hesitates to share test reports or a DoC may be hiding something.

- Outdated or Irrelevant Reports: The report should be recent and for the specific material you are buying. A test on a different product is useless.

- Unbelievably Low Prices: If a price seems too good to be true, they are likely cutting corners. Proper materials, manufacturing, and third-party testing cost money.

- Lack of Knowledge: If they can’t answer your specific questions about regulations, they are not the expert partner you need.

Your supplier is your first line of defense. Partnering with a specialist like us at Ecosourcecn means you are working with a team that lives and breathes these regulations. We believe in full transparency because your success is our success.

Conclusion

Importing bamboo food contact materials doesn’t have to be a regulatory maze. By understanding the key rules in the EU and North America, focusing on testing for substances like formaldehyde, and demanding complete documentation from a knowledgeable supplier, you can ensure compliance. This protects your brand, keeps consumers safe, and guarantees a smooth supply chain.