Struggling with eco-product rules? You’re not alone. Making sure your biodegradable coffee stirrers meet all the standards can feel overwhelming, right? But it’s key for market access.

Yes, ensuring your biodegradable coffee stirrers are FDA and EU compliant involves meeting specific food contact material regulations. This means testing for safety, proper material sourcing, and often, clear labeling about their composition and disposal – it’s totally doable with the right info!

So, you’ve got these fantastic biodegradable coffee stirrers, and you’re ready to take on the US and EU markets. That’s awesome! But then, bam! The whole world of regulations hits you. It’s a bit like planning a great road trip and then realizing you need a different visa for every state and country. Don’t worry though, once you break it down, it’s not as scary as it seems. Let’s dive into what you actually need to know to get your stirrers across the finish line, without pulling your hair out. Trust me, I’ve been there, and figuring this stuff out is a game-changer.

What Key FDA Rules Must My Biodegradable Stirrers Actually Meet in the US?

Selling in the US? The FDA has rules. If your stirrers touch food (and coffee stirrers do!), they need to be safe. Ignoring this can lead to big problems.

For FDA compliance, your biodegradable coffee stirrers must meet Food Contact Substance (FCS) requirements. This primarily involves ensuring materials are listed under 21 CFR parts 174-186 or are Generally Recognized As Safe (GRAS), preventing harmful substance migration into coffee.

Okay, so the FDA. Their main job is consumer safety. When we talk about coffee stirrers, they fall under "Food Contact Materials." The big document you’ll hear about is Title 21 of the Code of Federal Regulations (CFR). Specifically, parts 174 through 186 cover indirect food additives. What does this mean for our stirrers, especially the biodegradable kind like PLA or CPLA or even coated paper ones? Well, the materials used must be authorized for food contact. This could be because they’re on an approved list, or they have a Food Contact Notification (FCN) that’s effective, or they’re GRAS – Generally Recognized As Safe. I remember when we first started looking into PLA, we had to double-check its status. Thankfully, many common bioplastics like PLA have a pretty good history here.

But it’s not just about the base material. Think about any colorants, additives, or coatings. Each component has to be safe too!

Key FDA Considerations for Biodegradable Stirrers:

| Aspect | Detail | Why it Matters for Stirrers? |

|---|---|---|

| Material Safety | Base polymers (e.g., PLA, PHA, PBS) and any additives must be approved for food contact. | Prevents harmful chemicals leaching into hot coffee. |

| Migration Limits | Testing to ensure that any substance migrating from the stirrer to the food is below safe levels. | Especially important with hot beverages that can speed this up. |

| GRAS Substances | Some materials are "Generally Recognized As Safe" and might not need premarket approval. | Can simplify the compliance process if applicable. |

| Good Manufacturing Practices (GMP) | Though not as explicit as EU GMP for FCM, following GMP is crucial for consistent safety. | Ensures quality control and product safety. |

I often tell clients like Jacky, don’t just assume "biodegradable" means "automatically FDA compliant." We had a case once where a supplier offered "eco-friendly" stirrers, but when we dug deeper, their colorant wasn’t cleared for food contact in the US! That was a close call. So, always ask for documentation and verify. It’s a bit like checking the ingredients on a food label – you want to know what you’re getting. It’s a pain sometimes, but better safe than sorry, right?

How Does the EU Approach Compliance for Eco-Friendly Coffee Stirrers Differently?

Thinking of European markets? The EU has its own set of rules, sometimes stricter. If your stirrers aren’t compliant, they won’t see a single café shelf there. Big opportunity missed!

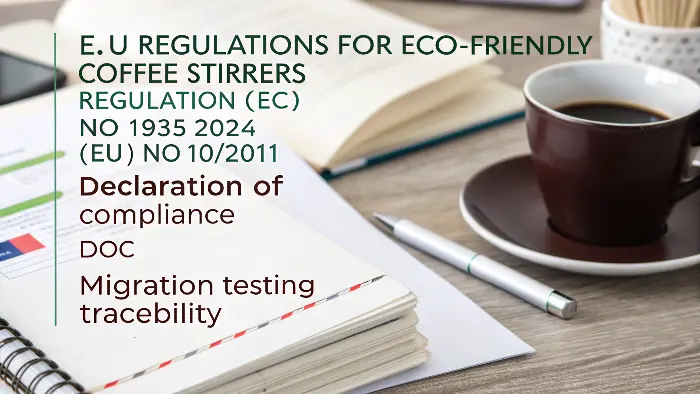

EU compliance for coffee stirrers hinges on Regulation (EC) No 1935/2004 (the framework) and (EU) No 10/2011 (for plastics, including bioplastics). This demands a Declaration of Compliance (DoC), migration testing, and traceability – often more detailed than FDA requirements.

Now, let’s hop over the pond to the European Union. They have a pretty comprehensive system too, and I’d say it’s generally seen as a bit more prescriptive in some areas, especially for plastics – and yes, bioplastics like PLA are treated as plastics. The main piece of legislation is the Framework Regulation (EC) No 1935/2004. This sets out the general principles: materials shouldn’t transfer their constituents to food in quantities that could endanger human health or bring about an unacceptable change in the composition of the food, or a deterioration in its organoleptic properties (taste and smell). That last bit about taste and smell is interesting, eh?

For plastic materials, including our biodegradable PLA or CPLA stirrers, the specific measure is Regulation (EU) No 10/2011. This is a big one. It lists authorized substances, and sets out rules for testing – especially migration testing. They look at Overall Migration Limits (OML) and Specific Migration Limits (SML) for certain substances. And a crucial document here is the Declaration of Compliance (DoC). This is basically a statement from the manufacturer (that’s us, Ecosourcecn, if we’re making them for you!) that the product complies with the relevant EU rules. The DoC needs to be passed down the supply chain.

EU Compliance Highlights for Stirrers:

| EU Requirement | Description | Implication for Stirrers |

|---|---|---|

| Regulation (EC) No 1935/2004 | General safety requirements for all Food Contact Materials (FCMs). | Stirrers must not be harmful or alter the coffee. |

| Regulation (EU) No 10/2011 | Specific rules for plastic FCMs, including bioplastics. Lists authorized substances, migration limits. | Key for PLA/CPLA stirrers. Requires specific testing. |

| Declaration of Compliance (DoC) | A mandatory document stating compliance, containing test info and material details. | Essential for market access; you’ll need this from your supplier or to provide it. |

| Good Manufacturing Practice (GMP) | Regulation (EC) No 2023/2006 mandates GMP for FCMs. | Ensures processes are in place for consistent safety and quality. |

| Traceability | Systems must be in place to trace materials throughout the supply chain. | Important for recalls or if issues arise. |

I remember a client who wanted to export wooden stirrers. While (EU) No 10/2011 is for plastics, the framework (EC) No 1935/2004 still applies. And then national rules in EU member states can also come into play for materials not harmonized at the EU level, like paper or wood. It’s a bit of a patchwork sometimes, but the core principle of safety and the DoC (where applicable) are key. It’s like having a passport (the DoC) that shows your stirrers are fit to travel through the EU market. It makes things smoother for everyone, especially for guys like Jacky who need that assurance.

Are Specific Material Tests Essential for Getting FDA and EU Approval for My Stirrers?

Just saying your stirrers are "safe" isn’t enough. Both FDA and EU want proof. Without proper testing, you’re just guessing, and that’s a risky business strategy.

Yes, specific material tests, particularly migration testing, are essential. These tests ensure that no harmful substances leach from the stirrers into beverages above permitted levels set by both FDA (e.g., 21 CFR) and EU (e.g., Regulation (EU) No 10/2011) food contact regulations.

Absolutely, testing is not just a good idea; it’s pretty much non-negotiable for both the FDA and EU, especially for new materials or formulations. Think about it: a coffee stirrer sits in hot, sometimes acidic, liquid. You need to be darn sure nothing yucky is leaching out of it. That’s where migration testing comes in. This is the big one. Labs will simulate how the stirrer interacts with coffee using food simulants – things like acetic acid for acidic foods, or ethanol solutions for fatty foods (though for coffee, it’s usually aqueous/acidic simulants). Then they measure what, if anything, has migrated from the stirrer into the simulant.

For the FDA, the acceptable levels are often tied to the regulations in 21 CFR for specific substances. They want to see that any migrating substances are below levels that could cause harm. For the EU, Regulation (EU) No 10/2011 is very specific about migration testing protocols for plastics. They define:

- Overall Migration Limit (OML): This is the maximum permitted amount of all non-volatile substances that can transfer from the plastic material to the food simulant. It’s generally 10 milligrams per square decimeter of surface area (mg/dm²) or 60 mg/kg of food simulant.

- Specific Migration Limits (SMLs): These are limits for individual authorized substances, based on their toxicity. Some chemicals have very low SMLs.

Common Tests Beyond Migration:

- Material Characterization: Identifying the exact composition of the stirrer.

- Heavy Metals Content: Checking for lead, cadmium, mercury, etc. Both regions have limits.

- Phthalates/BPA: Depending on the material, tests for these controversial chemicals might be needed. (Though for most common biodegradable stirrer materials like PLA or wood, BPA isn’t usually an intrinsic issue, but good to be aware of).

- For compostability claims (more on this later): Tests like ASTM D6400 (US) or EN 13432 (EU) if you’re marketing them as "compostable."

I remember when we were developing a new CPLA stirrer formula. We thought we had everything right, but the initial migration tests for the EU were borderline on one substance. We had to go back, tweak the formulation slightly, and re-test. It added a couple of weeks and some cost, but it was essential. You can’t cut corners here. It’s like baking a cake – you need to follow the recipe (the regulations) and check if it’s cooked properly (testing) before you serve it. For someone like Jacky, providing these test reports upfront builds a massive amount of trust. He needs to know his brand is protected.Beyond Tests: What About Labeling and Certifications for Compliant Stirrers in these Markets?

Passed the tests? Great! But how do you communicate this to customers and authorities? Clear labeling and recognized certifications are not just nice-to-haves; they’re often required and build trust.

Clear labeling is vital. For the EU, the "food safe" symbol (cup and fork) might be used. Certifications like BPI (US) or TÜV Austria’s OK compost (EU) for compostability are also key for market positioning, alongside the necessary Declaration of Compliance for EU plastics.

So, your stirrers are safe, they’ve passed the tests – fantastic! Now, how do you tell the world, or at least your customers and the regulatory bodies? This is where labeling and certifications come into play. They are super important.

Let’s start with labeling for food contact compliance. In the EU, for materials that aren’t obviously intended for food contact (though stirrers usually are), you might need the "cup and fork" symbol, or the words "for food contact." You also need to provide information for traceability, like batch numbers, and the name and address of the manufacturer or seller. And remember that Declaration of Compliance (DoC)? That’s a key piece of "documentation" more than a "label" on the product itself, but it must accompany the goods.

For the FDA, the labeling requirements for food contact safety are less explicit on the product itself compared to the EU’s symbol, but the underlying compliance and ability to prove it are essential. The main thing is that your product is compliant, and you have the paperwork to back it up if questioned.

Now, let’s talk about eco-claims and certifications, which are a big deal for biodegradable stirrers.

If you claim your stirrers are "biodegradable" or "compostable," you better be able to back that up. This is where third-party certifications are golden.

- In the US: The main certification for compostability in industrial facilities is from the Biodegradable Products Institute (BPI). They certify products against ASTM D6400 or D6868 standards. Seeing that BPI logo gives consumers and composters confidence.

- In the EU: TÜV Austria is a major certifier. They offer various "OK compost" marks:

- OK compost INDUSTRIAL (EN 13432): For items compostable in industrial facilities. This is the most common one for food service items.

- OK compost HOME: For items that can be composted in a home compost bin (stricter conditions).

- There are also seedling logos based on EN 13432.

Why Certifications Matter:

Certification Type Key Standard(s) Region Focus Benefit BPI Certified Compostable ASTM D6400/D6868 USA Verifies industrial compostability, builds trust, prevents greenwashing. TÜV OK compost INDUSTRIAL EN 13432 EU Verifies industrial compostability according to EU standards. TÜV OK compost HOME (Proprietary/EN based) EU Verifies home compostability, a premium claim. FSC (for wood/paper) FSC Standards Global Ensures wood/paper comes from responsibly managed forests. I always advise my clients, especially those serious about sustainability like Jacky, to go for these certifications if their product qualifies. It’s an investment, sure. The testing for EN 13432, for example, isn’t cheap and takes time. But it avoids accusations of "greenwashing." We, at Ecosourcecn, make sure our certified products have all the paperwork in order. It just makes life easier for everyone down the line. It’s like getting a gold star in school – it shows you’ve done your homework and met the standard! 🔥 It’s not just about compliance; it’s about building a brand that people trust. And in the eco-friendly space, trust is everything.

Conclusion

Navigating FDA and EU rules for stirrers takes effort, but it ensures safety and market access. With the right info and partners, it’s totally achievable!