Worried about the cost of going green? Many coffee shop owners are. You want sustainable options, but the budget is tight. It’s a common dilemma!

Switching to biodegradable coffee accessories often involves a higher upfront cost, but offers long-term benefits in brand image, customer loyalty, and environmental responsibility.

I get it. "How much is this really going to cost me?" – that’s probably the first question on your mind when you think about ditching plastic for eco-friendly alternatives in your cafe. It’s a fair question! You’re running a business, and every penny counts. When I talk to buyers like Jacky, a packaging specialist for a Canadian eco-conscious brand, this is always a key part of our conversation. He needs solutions that are not just green, but also commercially viable. The good news is, while there can be an initial difference, the bigger picture often shows it’s a smart investment. Let’s break down the costs so you can see what to expect. It’s probably not as scary as you think, and the payoff can be huge!

How Much More Does Biodegradable Plastic Actually Cost Compared to Regular Plastic?

Heard eco-plastics are pricier? It’s a common concern. You need the facts to budget effectively for your cafe’s sustainable switch.

Biodegradable plastics, like PLA, can cost 20% to 100% more than conventional plastics like PET or PS, due to raw material sourcing and production scale.

Alright, let’s tackle the big one: the price difference between biodegradable plastics (like PLA, which we use a lot for cold cups and cutlery) and their traditional, oil-based cousins. Truth be told, yes, biodegradable plastics often come with a higher price tag per unit. I’ve seen figures ranging anywhere from a 20% increase to sometimes double the cost, depending on the specific type of plastic, the application, and the volume you’re buying. When Jacky first started sourcing PLA products, this was a hurdle he had to address with his team.

Why the Price Difference? Let’s Look Closer:

- Raw Material Sourcing: Conventional plastics are made from fossil fuels, which, despite their environmental toll, have a long-established and massive-scale extraction and refining infrastructure, making them relatively cheap (for now!). Biodegradable plastics like PLA are typically derived from renewable resources like corn starch or sugarcane. Growing, harvesting, and processing these plant-based feedstocks involve different agricultural and fermentation processes that can, at present, be more costly than drilling for oil.

- Production Complexity & Scale: The technology for producing bioplastics is newer and still evolving. Manufacturing processes might be more specialized, and the global production volume is still much smaller than that of traditional plastics. Think about it – conventional plastics have had a nearly century-long head start in terms of optimizing production and achieving economies of scale! As demand for bioplastics grows, we’re seeing these costs come down, but there’s still a gap.

- Research & Development (R&D): A lot of investment is still pouring into R&D for bioplastics to improve their properties, reduce costs, and find new applications. These R&D costs are often factored into the current pricing.

When I work with businesses through Ecosourcecn, we try to mitigate these costs. Because we deal in volume and have established relationships with manufacturers, we can often secure more competitive pricing than a single cafe might on its own. Jacky often tells me that partnering with a supplier who understands these nuances and can offer scalable solutions is key to making the switch financially feasible for the brands he supports. So, while the label price might be higher, the story doesn’t end there.Is Biodegradable Packaging Generally More Expensive Than Traditional Plastic Packaging?

Wondering if all eco-packaging breaks the bank? It’s a valid question when considering a full switch for your coffee accessories and takeout containers.

Yes, biodegradable packaging often has a higher unit cost than conventional plastic, but the gap is narrowing, and "value" extends beyond just price.

So, we’ve talked about biodegradable plastics like PLA. But what about the broader category of biodegradable packaging? This includes things like sugarcane bagasse containers, FSC-certified paper products, bamboo stirrers, and those CPLA lids for your coffee cups. Generally speaking, yes, these items often carry a premium over their cheapest non-biodegradable plastic counterparts. I’m not going to sugarcoat it; if you’re comparing a flimsy, single-use plastic fork to a sturdy, compostable CPLA fork, the CPLA one will likely cost more upfront.

Looking Beyond the Unit Price – The Real Value:

It’s super important to look beyond just the per-item cost. This is something Jacky emphasizes constantly when he’s evaluating new packaging options. He asks, "What’s the total value we’re getting?"

- Material Variety & Performance: Different biodegradable materials come with different price points and performance characteristics. For example:

- Sugarcane Bagasse: Made from an agricultural byproduct, it’s often very cost-effective for items like plates and clamshells. It’s sturdy, microwaveable, and compostable. The value here is immense because it turns waste into a resource.

- CPLA (Crystallized Polylactic Acid): Used for hot cup lids and heat-resistant cutlery. It’s more expensive than standard PLA or basic plastic because of the extra processing step to make it stronger and more heat tolerant. But, it performs brilliantly, which customers appreciate. No one wants a floppy fork or a lid that melts!

- FSC-Certified Paper: For cups and some food wraps, using paper from responsibly managed forests might add a small premium, but it guarantees sustainability and supports ethical sourcing.

- Brand Image and Customer Appeal: This is huge. How much is it worth to you for customers to see you as a responsible, forward-thinking business? Using visibly eco-friendly packaging can significantly boost your brand image and attract customers who prioritize sustainability. Jacky has seen firsthand how brands using eco-packaging gain a loyal following. This is an intangible benefit that often outweighs the slight increase in packaging cost.

- Avoiding Future Costs: Think about potential future plastic taxes or stricter regulations. By switching now, you’re future-proofing your business.

- Reduced Contamination Issues: For cafes serious about composting, using certified compostable packaging for everything simplifies waste streams and ensures food scraps aren’t contaminated by non-compostable plastics.

At Ecosourcecn, we help our clients navigate these choices. We can show you cost comparisons, but we also discuss the performance and the message each material sends. Sometimes, a slightly more expensive option is actually the better value when you consider everything. It’s not just about pennies per piece; it’s about the dollars and sense of building a sustainable brand.Are Biodegradable Bags Cheaper or More Expensive to Produce Than Plastic Ones?

Considering eco-friendly bags for coffee beans or waste? Cost is always a factor. You need to know if this switch fits your budget.

Biodegradable bags, especially those with barrier properties for food or certified compostable ones, are typically more expensive to produce than standard polyethylene plastic bags.

This is a specific one, but important, especially if you sell retail coffee beans or are thinking about compostable bin liners for your cafe’s organic waste. When we talk about bags – whether it’s a small bag for a pastry, a larger one for coffee grounds, or even retail packaging for your beans – the cost question comes up again. And, generally, biodegradable bags are more expensive to produce than your standard, super-cheap polyethylene (PE) plastic bags. I wish I could say otherwise, but that’s the current reality.

Digging into the "Why" for Bag Costs:

Why the higher price tag for these green alternatives?

- Specialized Polymers and Films: The raw materials, like PLA or other compostable resins (sometimes blends are used to achieve specific properties), are more expensive than PE resins, as we discussed earlier. Producing the film itself can also be a more nuanced process.

- Barrier Properties (Especially for Coffee): This is a big one for coffee bean bags. Coffee needs protection from oxygen, moisture, and light to stay fresh. Traditional coffee bags often use layers including aluminum or plastic films that are great for barrier but terrible for recycling or composting. Creating biodegradable/compostable bags with similar high-barrier properties often involves more complex, multi-layer structures using specialized bio-films. These advanced materials and the technology to combine them effectively add to the cost. Jacky spends a lot of time sourcing coffee packaging that balances freshness with eco-credentials, and it’s a tricky (but achievable!) balance.

- Certification Costs: If you want your bags to be certified compostable (e.g., by BPI or TÜV Austria), there are testing and certification fees that manufacturers need to cover, and this gets passed down the line. But this certification is golden – it tells your customers the bag truly is what it claims to be.

- Smaller Production Runs: While growing, the demand for specialized biodegradable bags is still smaller than for PE bags, so manufacturers don’t always achieve the same massive economies of scale.

I remember a cafe owner I worked with who wanted to switch their bin liners to compostable ones to streamline their organic waste collection. Initially, the per-bag cost was a bit of a shock compared to the cheap black plastic bags they were used to. But once they factored in the ease of sending everything (food scraps + bag) to the composter and the positive message it sent to staff and customers, the slightly higher cost felt justified. At Ecosourcecn, we can source various types of biodegradable bags, from simple PLA produce bags to more complex, high-barrier packaging, and we always aim to find the best balance of performance, sustainability, and cost for our clients.What’s the Price Tag on Making a Single Biodegradable Cup?

Curious about the cost of that eco-friendly coffee cup? Understanding the breakdown helps in making informed purchasing decisions for your cafe.

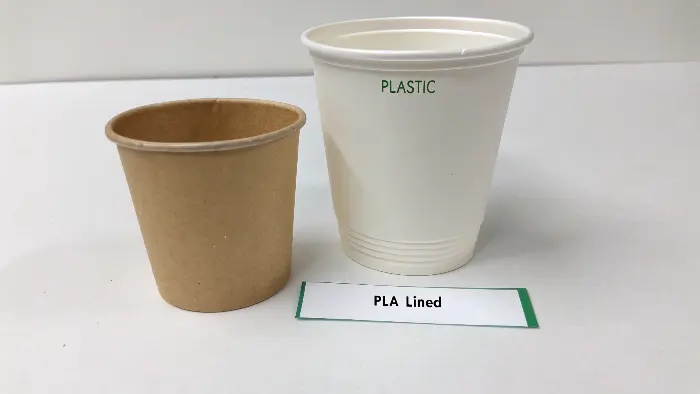

A single biodegradable paper cup (PLA-lined) typically costs a few cents more than a traditional plastic-lined cup, factoring in materials, production, and certification.

Let’s zoom in on one of the most common items in any cafe: the humble coffee cup. What actually goes into the cost of a biodegradable paper cup, the kind that’s usually lined with PLA (polylactic acid) to make it waterproof and compostable? It’s more than just paper and a bit of "green stuff"! When I’m discussing options with clients like Jacky, who need to source thousands of these, we look at all the contributing factors.

Anatomy of a Biodegradable Cup’s Cost:

Breaking it down, here are the key components that influence that final per-cup price:

- Paperboard Quality & Sourcing: The base of the cup is paperboard. Is it from virgin pulp or recycled content? Crucially for eco-credentials, is it FSC-certified (Forest Stewardship Council), guaranteeing it comes from responsibly managed forests? FSC certification often adds a small premium, but it’s a hallmark of true sustainability that brands like Jacky’s look for. The weight and quality of the paperboard also play a role – a sturdier, double-walled cup will cost more than a single-wall.

- PLA Resin and Coating: The PLA resin used for the waterproof lining is, as we’ve discussed, generally more expensive than the polyethylene (PE) used in conventional plastic-lined cups. The process of coating the paperboard with PLA also has its own associated costs.

- Manufacturing & Printing: Forming the cup, rolling the rim, attaching the base – these are all manufacturing steps. Then there’s printing. A plain white cup is cheapest. A one-color custom print costs more. A full-color, complex design? Even more. We at Ecosourcecn often help clients find a sweet spot between branding impact and cost-effective printing.

- Lids (CPLA): Don’t forget the lid! A CPLA (crystallized PLA) lid, which is heat-resistant and compostable, will also be more expensive than a standard polystyrene plastic lid.

- Volume & Logistics: Like any manufactured product, the larger the order quantity, generally the lower the per-unit cost due to economies of scale in production and raw material purchasing. Shipping and logistics also factor in.

- Certification: If the cup is certified compostable (e.g., BPI or EN13432), those certification costs are embedded in the price. This is a non-negotiable for many reputable brands because it provides assurance.

So, if a conventional plastic-lined cup costs, say, X cents, a comparable biodegradable PLA-lined cup might cost X + 2 to 5 cents (this is just a rough example, actuals vary hugely!). It might seem small per cup, but multiply that by thousands of cups a month, and it adds up. However, Jacky often points out that this small premium is an investment in the brand’s values and its appeal to the growing number of eco-conscious consumers. It’s a visible statement that "we care." And that, for many businesses, is priceless.Conclusion

While biodegradable accessories may have higher initial costs, they offer significant long-term value, enhancing your cafe’s brand and attracting eco-conscious customers. It’s an investment in sustainability.