Are you trying to switch your beverage chain to eco-friendly packaging, but the costs are holding you back? It often feels like a choice between protecting your profit margins and protecting the planet. This constant battle can be frustrating. Smart bulk ordering strategies offer a way out, letting you achieve both sustainability and affordability.

The best way to minimize costs with bulk ordering is to move beyond simple volume discounts. Focus on strategic forecasting, consolidating your packaging SKUs, and partnering with a supplier for phased deliveries. This approach secures lower per-unit prices while also reducing freight expenses and warehousing fees. It makes sustainable packaging a financially smart decision, not just an ethical one. You get the benefits of bulk buying without the logistical headaches.

This might sound simple on the surface, but the real savings are found in the details of your strategy. It’s not just about buying more; it’s about buying smarter. To truly benefit, you need to rethink your entire procurement process from the ground up.

Let’s dive into the specific tactics that will make a real difference for your business and the environment.

Beyond Volume: How Does SKU Consolidation Cut Hidden Costs?

Does your inventory feel overly complicated? You probably have different cups, lids, sleeves, and straws for every type of drink you offer. This complexity creates hidden costs in storage, management, and waste from obsolete stock. It feels chaotic and unnecessarily expensive. A smarter approach could unlock significant savings you haven’t considered.

SKU consolidation is the process of redesigning your packaging lineup to use fewer unique items across your menu. For example, you could adopt one lid size that fits multiple cups or use a single cup design for both hot and cold drinks. This dramatically increases your order volume for each remaining item. This allows you to unlock better pricing and radically simplifies your entire supply chain, from ordering to in-store operations.

The power of SKU consolidation lies in its ability to attack costs that don’t appear on the supplier’s invoice. These are the "hidden" operational expenses that eat into your profits. Every unique item, or Stock Keeping Unit (SKU), you carry requires warehouse space, administrative oversight for reordering, and the risk of becoming dead stock if a product is discontinued.

I remember working with a regional coffee chain that was struggling with this. They had unique custom-printed cups and lids for their 8oz, 12oz, and 16oz sizes. That’s six different SKUs just for their core hot cups. By helping them switch to cups that shared a single lid diameter, we cut their lid SKUs from three to one. This immediately tripled the order volume for that one lid, which dropped its per-unit cost by 15%.

Here’s a simple breakdown of the impact:

| Metric | Before Consolidation | After Consolidation |

|---|---|---|

| Lid SKUs | 3 (8oz, 12oz, 16oz) | 1 (Universal fit) |

| Total Annual Lid Order | 3,000,000 units | 3,000,000 units |

| Avg. Volume per SKU | 1,000,000 units | 3,000,000 units |

| Unit Price | $0.05 | $0.0425 |

| Inventory Complexity | High | Low |

| Risk of Waste | Moderate | Low |

This strategy also simplifies life for your staff. With fewer components to manage, baristas can work faster and make fewer mistakes, improving customer service. You maintain branding through custom-printed cups or even more flexible options like branded sleeves or stickers, which are cheaper to produce and store. It’s a win-win: lower costs and smoother operations.

Is Phased Delivery the Secret to Affordable Bulk Orders?

You see the incredible per-unit savings on an order of a million cups, but a huge question stops you: where would you even store it all? Paying for a year’s worth of inventory upfront ties up cash, and warehousing fees can quickly erase your savings. This logistical nightmare makes large-scale sustainable procurement feel impossible.

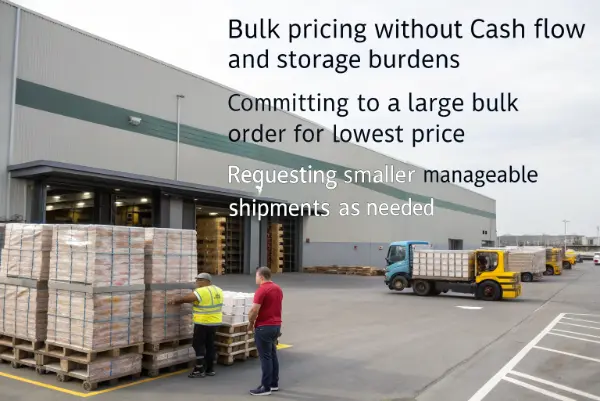

Phased delivery, also known as a call-off stock agreement, is the solution. You commit to a large bulk order with your supplier to lock in the lowest possible price. However, instead of receiving the entire shipment at once, the supplier holds the inventory for you. You then "call off" or request smaller, manageable shipments as you need them—monthly or quarterly. This gives you the best of both worlds: bulk pricing without the cash flow and storage burdens.

This strategy is a game-changer for businesses that want to scale their sustainability efforts without scaling their warehouse space. The core benefit is financial flexibility. You commit to the volume, which allows us as the manufacturer to plan production efficiently and pass those savings on to you. But you only pay for the portion of the order that you receive in each shipment. This keeps your cash flow healthy and available for other business needs.

Let’s break down how this works in practice. Imagine you need 1.2 million PLA cold cups for the year.

The Traditional Approach

You might place four separate orders of 300,000 cups each quarter. Your price is based on the 300k quantity. You have to find space for all 300,000 cups every three months, and your unit price is higher.

The Phased Delivery Approach

You place one single order for 1.2 million cups. We give you our best price based on that massive volume. Then, we agree on a delivery schedule. We might ship you 100,000 cups every month. You get a steady supply, you never run out of stock, and your storage footprint is minimal. Most importantly, you pay the low 1.2-million-unit price for every single cup. This approach also protects you from price volatility. By locking in a price for the entire year, you are shielded from unexpected increases in raw material or shipping costs. It makes budgeting predictable and stable. At Ecosourcecn, this is a core service we offer to our partners, because we believe making sustainability accessible means solving these real-world logistical challenges.

How Can Customization Actually Lower Your Long-Term Costs?

You might think that custom-printed or uniquely designed packaging is a luxury that adds to your expenses. When you’re focused on minimizing costs, standard, off-the-shelf products seem like the only logical choice. This short-term thinking can actually cost you more in the long run by missing key opportunities for efficiency and brand building.

Strategic customization can significantly lower long-term costs by optimizing your packaging for operational efficiency and supply chain logistics. This involves designing multi-functional items, such as a cup that works for both hot and cold drinks, or creating packaging that nests tightly to reduce shipping volume. These smart design choices reduce the number of SKUs you need to manage and cut down on freight and storage expenses, delivering savings that far outweigh the initial design investment.

Investing in smart design upfront is one of the most effective cost-reduction strategies. Standard products are made for the average user, but your business has specific needs. Customization allows you to create packaging that is perfectly tailored to your menu and operations.

A few years ago, we worked with a smoothie chain that was using separate plastic cups for their smoothies and paper bowls for their acai bowls. That meant two different SKUs, two separate inventory streams, and two sets of lids. We helped them design a single, custom-molded bagasse bowl with a wide mouth that was perfect for both. It was sturdy enough for a thick smoothie and wide enough for spooning acai. We also designed a single flat PLA lid to fit it.

The results were transformative:

- Reduced SKUs: They went from four items (cup, cup lid, bowl, bowl lid) down to just two (the universal bowl and its lid).

- Lower Freight Costs: The new bagasse bowls were designed to nest very tightly, meaning we could fit 30% more units on a single pallet. This directly translated to lower shipping costs per unit.

- Stronger Branding: The unique, custom-designed bowl became a signature part of their brand experience. Customers loved the feel of the sturdy, eco-friendly material.

This is where a good supplier acts more like a partner than a vendor. We can advise on material choices (e.g., is PLA or bagasse better for your specific use?), design tweaks for stackability, and opportunities to create multi-use items you may not have considered. This collaborative approach turns an expense—packaging—into a strategic asset that saves you money and strengthens your brand identity.

Do Eco-Certifications Provide More Than Just Marketing Value?

You see certifications like BPI, EN13432, and FSC on eco-friendly products, and you might assume they are mainly for marketing. You think they just provide a nice logo to put on your cups to appeal to green-conscious consumers. While they are great for marketing, their real value runs much deeper and can directly impact your operational success and risk management.

Yes, eco-certifications provide critical value far beyond marketing. They are your assurance that a product will perform as advertised and comply with regional and national regulations. For example, BPI or EN13432 certification guarantees an item is truly compostable, protecting you from greenwashing claims and ensuring acceptance by commercial composting facilities. This validation is essential for operational integrity, legal compliance, and maintaining brand trust with your customers.

Relying on a supplier’s verbal promise that a product is "eco-friendly" is a significant business risk. Without third-party validation, you open yourself up to a host of problems. As a packaging specialist like Jacky would know, the details matter. A product might be made from plant-based material, but if it doesn’t break down properly in a commercial facility, it’s just another piece of trash.

Here’s why these certifications are non-negotiable for any serious business:

1. Regulatory Compliance

Many regions, especially in Europe and parts of North America, have strict laws about what can be marketed as "compostable" or "biodegradable." Using non-certified products could lead to fines and legal trouble. Certifications like ASTM D6400 (the basis for BPI) in the US and EN13432 in Europe are the gold standard. They ensure you are legally compliant.

2. Operational Viability

Your sustainability plan only works if your waste partners accept your packaging. Commercial composting facilities will often reject entire loads if they are contaminated with non-compostable materials. BPI and CMA (Compost Manufacturing Alliance) certifications are often required by these facilities. Without them, your "compostable" cups will end up in a landfill, defeating the entire purpose of your investment.

3. Risk Mitigation

Certifications protect your brand’s reputation. The last thing you want is to be accused of greenwashing. Third-party verification from a trusted body proves your commitment is genuine. It builds trust not only with customers but also with corporate partners and investors who are increasingly focused on environmental, social, and governance (ESG) criteria. At Ecosourcecn, we ensure every certified product we sell has the documentation to back it up, giving you peace of mind.

Conclusion

Maximizing sustainability while minimizing costs is not a zero-sum game. By moving beyond basic volume buys and embracing strategies like SKU consolidation, phased deliveries, and smart customization, you can build an efficient and affordable eco-friendly packaging program. Partnering with a supplier who understands these complexities is key to unlocking a truly sustainable and profitable future for your beverage chain.