Are you struggling to keep up with the complex web of global environmental regulations? The fear of shipments being rejected, facing heavy fines, or damaging your brand’s reputation over a compliance mistake is very real. You need a clear path to ensure your eco-friendly products meet the standards of every market you enter.

Navigating global green regulations involves three key steps. First, identify the essential certifications for your target markets, such as BPI for North America or EN 13432 for the EU. Second, understand the specific regional laws, like plastic taxes or single-use plastic bans. Finally, partner with a knowledgeable supplier who can provide complete and verified documentation for every product, ensuring a smooth and compliant import process from start to finish.

The world of sustainability is exciting, but it’s also filled with rules that can feel overwhelming. I remember working with a client, Jacky from Canada, who was incredibly passionate about his brand’s mission but felt lost in the maze of compliance paperwork. It’s a common story. But breaking down this challenge into manageable pieces can turn a major headache into a competitive advantage. Let’s dive into the specifics so you can import with confidence.

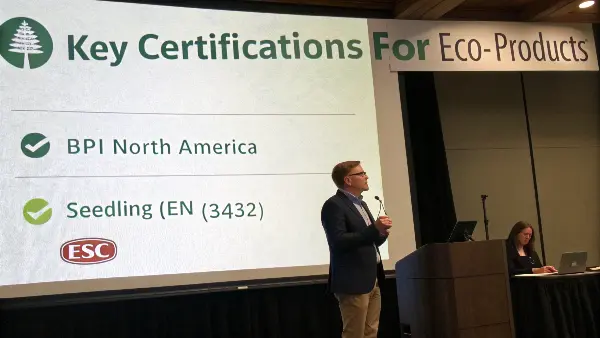

What Key Certifications Should Importers Prioritize for Eco-Products?

You’ve found a great new line of compostable tableware, but the product is covered in logos and certification marks you don’t recognize. How do you know which ones actually matter for your customers and your market? Choosing a product with the wrong certification can mean it ends up in a landfill, defeating the entire purpose of your sustainable mission.

For successful market entry, prioritize certifications recognized by your target region. In North America, BPI (Biodegradable Products Institute) is the gold standard for compostability. For the European Union, look for the "Seedling" logo (EN 13432) from organizations like TÜV AUSTRIA or DIN CERTCO. For paper and wood products, the FSC (Forest Stewardship Council) certification is globally recognized and ensures responsible sourcing. These marks are non-negotiable for credibility.

Understanding the right certifications is the first step toward building trust and ensuring compliance. It’s not just about having a logo; it’s about what that logo promises. A certification is a third-party guarantee that your product does what it claims to do. For an importer like Jacky, this is crucial. He needs to know that the bagasse containers he’s sourcing will break down in an industrial composting facility as promised. Let’s break down the most important ones.

Major Certifications for Market Access

The certification landscape can be confusing, but a few key players cover most major markets. Focusing on these will simplify your sourcing process.

- Compostability Certifications: These confirm a product will biodegrade within a specific timeframe under controlled conditions (i.e., in an industrial composting facility). They are vital for food service items.

- Responsible Sourcing Certifications: These verify that the raw materials used in your products, like paper or wood, come from sustainably managed sources.

Here is a quick reference table to help you distinguish between the top-tier certifications you’ll encounter.

| Certification | Region | Material Focus | What It Guarantees |

|---|---|---|---|

| BPI | North America | Bioplastics, Fiber | Meets ASTM D6400 or D6868 standards for industrial compostability. |

| EN 13432 (Seedling) | European Union | Packaging, Bioplastics | Products will disintegrate and biodegrade fully in industrial composting. |

| TÜV AUSTRIA (OK compost) | Global / EU | Bioplastics, Inks | Offers various marks, including "OK compost INDUSTRIAL" and "OK compost HOME". |

| FSC | Global | Paper, Wood | Materials are sourced from forests managed responsibly for environmental and social benefit. |

Always ask your supplier for the certificate number and verify it on the certifying body’s public database. This simple check protects you from false claims.

How Do Green Regulations Vary Between the EU, North America, and Australia?

Imagine your shipment of biodegradable cutlery, perfectly compliant in the United States, gets held up by customs in France. Each country or region has its own set of rules, and what works in one place might be banned in another. This uncertainty creates huge risks for your supply chain, leading to costly delays and potential losses.

Major markets have distinct approaches to green regulations. The EU is very strict, with its Single-Use Plastics Directive banning specific items and France’s AGEC law adding labeling requirements. North America is a patchwork of state and city-level rules, like California’s strict compostability laws. Australia has a national plan to phase out problematic plastics, focusing on material and product type. You must research the specific laws at your port of entry.

This regional variation is one of the biggest challenges for importers. A "one-size-fits-all" approach simply doesn’t work. We once helped a client who wanted to use the same PLA-lined paper cup for their cafes in Toronto and Berlin. We had to explain that while the product was fine for Canada, Germany’s packaging laws required specific registration and potential fees under their Extended Producer Responsibility (EPR) scheme. Understanding these differences is not just about compliance; it’s about smart business strategy.

Navigating Key Regional Directives

Let’s look at the core differences you need to be aware of. Success depends on treating each market as a unique entity.

-

The European Union (EU): The EU is a leader in environmental legislation. The Single-Use Plastics (SUP) Directive is a key piece of legislation that restricts items like plastic cutlery, straws, and polystyrene food containers. Furthermore, countries within the EU, like France with its AGEC law, have additional requirements for labeling, repairability, and waste. Extended Producer Responsibility (EPR) is another huge factor in the EU, where importers are financially responsible for the end-of-life of their packaging.

-

North America (USA & Canada): There is no single federal ban on plastics here. Instead, it’s a mix of regulations at the state/province and city level.

- USA: California is a leader with its "Truth in Labeling" laws, which strictly regulate the use of terms like "compostable" or "biodegradable." Many other states and cities have their own specific plastic bag bans or restrictions on polystyrene foam.

- Canada: The federal government has moved to ban several single-use plastic items nationwide, including checkout bags, cutlery, and straws.

-

Australia: Australia is taking a national approach through its National Plastics Plan. The government is working with states to phase out certain types of plastics and packaging. This includes a push for 100% reusable, recyclable, or compostable packaging and the elimination of problematic single-use plastics.

Knowing these differences will help you tailor your product sourcing and avoid costly surprises at the border.

What Are the Real Costs of Ignoring Environmental Compliance?

You might be tempted to cut corners or trust a supplier’s verbal promise about compliance to save a little money upfront. But what happens when that container of goods is flagged by customs? The potential financial hit from fines, storage fees, or even the total loss of your shipment can far outweigh any initial savings you thought you made.

Ignoring environmental compliance can lead to devastating financial and reputational costs. These include hefty fines from regulatory bodies, seizure and destruction of your imported goods at your own expense, and forced product recalls. Beyond the direct costs, your brand can suffer severe damage, losing the trust of eco-conscious consumers who expect you to be diligent. Ultimately, non-compliance can shut you out of key markets entirely.

The risks are not abstract; they are very real. I’ve seen firsthand how a simple documentation error can spiral into a logistical nightmare. A European client of ours almost had a full container of custom-printed coffee cups rejected because their previous supplier failed to provide the proper migration test reports required under EU food contact material regulations. The cost of storage while sorting it out, plus the air-freight for the correct paperwork, was enormous. This is why due diligence isn’t just a box-ticking exercise; it’s a fundamental part of risk management.

Breaking Down the Consequences

The total cost of non-compliance goes far beyond a simple fine. It’s a chain reaction of negative events that can impact every part of your business.

-

Direct Financial Penalties:

- Fines: Governments impose significant fines for importing non-compliant goods. These can range from thousands to hundreds of thousands of dollars, depending on the infraction.

- Shipment Rejection: Your goods can be refused entry. You are then responsible for the cost of either shipping them back to the origin country or paying for their destruction.

- Storage and Demurrage Fees: Every day your container sits at the port while you try to resolve a compliance issue, you rack up expensive storage (demurrage) fees.

-

Indirect and Reputational Costs:

- Brand Damage: In today’s market, customers choose brands that align with their values. A compliance failure reported in the media can quickly erode years of brand trust.

- Loss of Market Access: Repeated offenses can get your company blacklisted, making it impossible to import into that region in the future.

- Supply Chain Disruption: A rejected shipment means you have no product to sell, leading to lost sales, broken contracts with distributors, and frustrated customers.

Investing in compliance upfront is not a cost—it’s an insurance policy against these potentially business-ending consequences.

How Can You Verify Your Supplier’s Sustainability Claims?

Every supplier says their products are "green" and "eco-friendly," but how do you know they’re telling the truth? It’s easy to get misled by vague marketing terms or even fake certificates. Trusting a supplier without doing your own research can put your entire business at risk if their products fail to meet the standards you promised your customers.

To verify a supplier’s claims, always demand specific documentation for each product. Ask for the full certification document, not just a logo, and verify the certificate number on the issuing body’s public online database (e.g., BPI’s or FSC’s website). Request material safety data sheets (MSDS) and food-grade compliance reports like FDA or LFGB. If possible, ask for a factory audit report from a reputable third-party like BSCI or Sedex.

Verification is a non-negotiable step in our process at Ecosourcecn. We treat documentation as seriously as the product itself. I always tell my clients, "Trust, but verify." It’s a simple mantra that can save you from a world of trouble. A reliable partner will be transparent and ready to provide all the necessary proof without hesitation. If a supplier is evasive or only gives you vague assurances, that is a major red flag. Your brand’s reputation rests on the claims you make, which are built on the proof your supplier provides.

A Checklist for Due Diligence

Creating a systematic verification process is key. You need to know what to ask for and where to look. This isn’t about being confrontational; it’s about being professional and thorough.

-

Certification Verification: As mentioned, this is your first and most important step. Don’t just accept a PDF of a certificate. Go to the source.

- For BPI, use their certified product catalog online.

- For FSC, use their public certificate search database.

- For TÜV AUSTRIA, they also have a database of certified product holders.

-

Technical & Safety Documentation: Eco-friendly doesn’t exempt you from safety standards, especially for food-contact items.

- Food Contact Reports: Ask for FDA (for the US) or LFGB (for Germany/EU) testing reports. These reports ensure no harmful chemicals can leach from the product into food.

- Technical Data Sheets (TDS): This document provides details about the product’s material composition, physical properties, and recommended usage conditions.

-

Factory and Social Compliance Audits: A truly sustainable supplier is also an ethical one.

- BSCI (Business Social Compliance Initiative): This is a widely recognized audit that assesses workplace conditions, fair wages, and worker safety.

- Sedex (Supplier Ethical Data Exchange): A platform where suppliers can share ethical data and audit reports with their customers.

A supplier who has these documents organized and ready is a supplier who takes compliance seriously.

What Role Does Your Supplier Play in Ensuring a Smooth Compliance Process?

You’re an expert in your market, not a global compliance lawyer. Trying to manage all the paperwork, testing reports, and changing regulations on your own is a full-time job. If your supplier just sends you the product and leaves you to figure out the rest, you are set up for failure. This lack of support can lead to critical mistakes.

A great supplier acts as your compliance partner, not just a vendor. They should proactively provide all necessary documentation organized for your specific market, including valid certifications, food-grade test reports, and technical data sheets. They should also keep you informed about changing regulations that could affect your products and help you navigate the complexities of customs clearance. Their expertise should make your job easier and safer.

This is the core of what we do at Ecosourcecn. We see ourselves as an extension of our client’s team. For instance, with our Canadian partner Jacky, we don’t just sell him bagasse containers. We provide a complete "compliance pack" for each shipment that includes the BPI certificate, FDA approval, and customs-ready commercial invoices. We even alerted him when a new labeling law was proposed in one of his target provinces. A supplier’s role must go beyond the product; it must include service and expertise that de-risks the entire import process for you.

Qualities of a True Compliance Partner

When you are evaluating suppliers, don’t just look at price. Look for a partner who can provide deep value through their support and knowledge. Here are the key things a proactive supplier should offer.

-

Organized and Proactive Documentation:

- They should have a well-organized system for all compliance documents and be able to provide them to you instantly.

- They should understand what documents are needed for your specific country and provide them without you having to ask for every single one.

-

Regulatory Expertise and Updates:

- A good supplier stays on top of global trends and changes in environmental law.

- They should be able to advise you if a product you’re buying might face issues in the future and suggest compliant alternatives.

-

Customization and Private Label Support:

- Your partner should understand that compliance extends to packaging and labeling. They should ensure that any custom printing or packaging meets the legal requirements of your destination market, such as using compostable inks or including mandatory disposal information.

-

Transparency and Traceability:

- They should be able to provide traceability for their raw materials, especially for certified products like FSC paper. This proves the integrity of their supply chain and reinforces the authenticity of their sustainability claims.

Choosing a supplier with this level of support transforms compliance from a stressful burden into a smooth, manageable part of your operations.

Conclusion

Navigating the world of global green regulations doesn’t have to be an impossible task. By prioritizing the right certifications, understanding key regional differences, and verifying every claim, you can protect your business. Most importantly, choosing a supplier who acts as a true compliance partner is the key to importing sustainable products with confidence and success.